Join us at Pack Expo Chicago and experience best-in-class processing and packaging solutions

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn morePanther Integrators

As an integrator or reseller, you’re looking for the best solutions to ensure your end-user has the best possible solution for all aspects of their material handling or supply chain operations. That’s where we come in.

We have the experience and expertise to get the job done. Handling logistics from receiving to shipping and everything in between. Panther will support you all the way with the most effective labeling automation solutions.

Additional Videos

This feature-rich – and all-electric label automation system is a durable, reliable option for exceptional print and apply performance.

The Panther Phantom is the evolution of label automation uptime. Featuring numerous applicator options, this system can be custom-configured to address your specific requirements to achieve maximum throughput.

A compact, pneumatic printer applicator for on-demand printing solutions that features configurable applicators for your case, flat item, packaging, and product labeling and barcode needs.

An entry-level on-demand labeling solution for greater integration into your growing operation.

A great solution for smaller volume operations that are looking to grow their label automation fulfillment processes.

Built for ultimate affordability and versatility, the entire system is engineered around a reconfigurable backbone that allows for horizontal, vertical, or custom arrangements – perfect for pre-printed labeling automation.

This innovative solution moves Panther printer applicators on a vertical axis to apply labels to cases and trays, as well as pallets at varying heights.

How can you label a pallet so that your forklift operator spends the maximum amount of time moving pallets and not incurring potential work-related injury by exiting and re-entering the forklift? Simple – by installing a Panther Industries print-and-apply system.

Whether it is a result of non-performing equipment, the need for additional production lines, or addressing manual procedures when preparing your outbound items, your bottom line could benefit from a boost in throughput.

Automate the pack slip and shipping label process with a solution from Panther Industries. Eliminate the labor-intensive process of an operator printing a pack list, folding it, placing it in an envelope, and then manually applying it to a package.

By utilizing tandem Predator printer applicators, remove the labor-intensive process of an employee printing, folding, and applying a pack slip and shipping label to your case or carton with our shipping and pack slip automation process.

With our NEXTStep label applicator, a shipping label and pack slip are printed simultaneously, folded, then applied to the item.

Ideal for carton and pallet labeling applications that features a durable carbon fiber swing arm that allows for various label sizes to be applied fast, and accurately.

Needing variable height pallet labeling solutions? No problem. Our Predator Printer Applicator with electric auto-height servo stand make pallet labeling easy and efficient.

Predator Printer Applicator with Tamp Applicator applying labels to pallets.

Adaptive touch technology allows the Predator Printer Applicator to label pallets and other items without damaging them.

Apply corner wrap labels to your cases and trays using the merge applicator with a brush-on option.

Apply labels to two sides of your pallets utilizing our Predator Printer Applicator with electric Swing Arm Applicator.

Increase throughput and efficiency with tandem Predator Printer Applicators for your flat items and packaging needs.

Utilize tandem printer applicators to increase throughput and efficiency when variable height labeling is a must.

The NEXTStep eliminates the need to manually print, fold, and apply a separate pack slip to your outbound package.

For increased throughput and efficiency, utilize tandem Predator Printer Applicators for all your cases and tray labeling needs.

Tandem Predator Printer Applicators applying secondary barcode labels to the side of cases.

Our fastest, most adaptive label application system ever. The Predator is built for speed – and accuracy – to boost your throughput and elevate your business.

Utilize Panther print-and-apply labeling systems in cross-dock and outbound shipping operations, warehouse, distribution, and fulfillment centers are able to improve their overall efficiency and throughput.

A specialty print and apply labeling solution for mail-order pharmaceutical labeling.

Utilizing our Phantom Printer Applicator with Swing Arm Applicator, easily apply labels to pallets.

A linear applicator for top and side label applications – primarily on packages, products, or pallets that are stationary or in motion.

Featuring numerous applicator options, this system can be custom-configured to address your company’s requirements to achieve maximum throughput.

By utilizing tandem Phantom Printer Applicators, eliminate downtime and increase productivity.

Label two sides of cases, trays, or bins utilizing tandem Phantom Printer Applicators with our Wipe Applicator.

Our flag applicator wraps around fine or smaller cylindrical items – such as cables, wires, tubes, hoses, and medical devices – to consistently and accurately apply a label much faster than what can be achieved manually.

Phantom Printer Applicator with Flag Applicator labeling products.

Our Shadow Printer Applicator with optional mounting stand allows for small production line labeling automation.

Our swing arm applicator configuration allows you to apply labels to the front, side, front + side, and corner wrap cases and trays as well as pallets.

Utilize our blow-on applicator for situations where direct contact with a product is not ideal, such as food, light/delicate items, or padded shipping envelopes.

Whether your company requires labeling of bags that are filled or flat, the application to this type of item presents numerous challenges. And in certain instances, you may require both a pre-printed and print-on-demand label applied to your bag.

With a swing arm application, labels can be applied to the front, side, both front and side, or around the corner of an item.

With a tamp blow applicator, the applicator extends in close proximity to the item (without contacting it), and then the label is blown onto the surface via a pneumatic system.

Using our Wipe Applicator, labels are wiped across the surface of the item as it passes by the applicator, typically in extreme, high-paced labeling operations.

The versatility of our all-electric swing arm applicator allows you to label the front and sides of pallets.

Apply multiple labels to pallets by utilizing our Swing Arm Applicator.

Our merge applicator features a brush or wrap option that directly applies a pre-printed label to a product or carton. Designed for applications where speed and accuracy are critical.

Available for both our all-electric and pneumatic systems, this single-axis applicator can be configured with variable reach lengths ideal for labeling cases and trays, as well as products.

This semi-automatic solution provides for greater speed, efficiency, and accuracy when a fully automated solution is not suited for your operations.

From cases and trays to pallets and bins, utilize our swing arm applicator for front and side labeling automation.

Our Tamp Applicator can not only label flat surface items but can also be used in some cases where a partial wrap may be needed on larger products.

Utilizing our Swing Arm Applicator, you can apply longer labels with limited height availability to cases and trays.

Our Flag Applicator wraps around fine or smaller cylindrical items such as cables, wires, tubes, hoses, and medical devices.

Utilize our Tamp Applicator for flat item labeling automation for mailers and specialty bag labeling.

Using tandem Printer Applicators, label various size cases and trays with ease.

For pre-printed corner wrap or security tab labeling, our corner wrap capabilities allow you to label your product packaging efficiently and accurately.

This semi-automatic solution provides for greater speed, efficiency, and accuracy when a fully automated solution is not suited for your operations.

Apply pre-printed labels to products using our tamp applicator.

Custom labeling automation solution using our Tamp Applicator to apply pre-printed labels to solid-state hard drives.

Apply pre-printed barcode labels in a fast-paced production line ensuring labeling accuracy and efficiency.

The Merge Applicator is a perfect solution for fulfillment operations that rely on a license plate number (LPN) barcode during picking, packing, and shipping processes to identify individual orders.

Apply larger labels utilizing our customer Swing Arm Corner Wrap Applicator to label cases and trays.

The swing blow applicator features a swing arm that presents the label prior to application on the front, side, or top of an item. The label is then blown onto the surface with minimal contact from the applicator surface.

The tandem swing blow applicators apply labels to assorted cases and feature a swing arm that presents the label prior to application on the front, side, or top of an item. The label is then blown onto the surface with minimal contact from the applicator surface.

For flat items and other building materials, the Merge Applicator is an optimum solution for applying product barcode labels.

The merge applicator is used to apply pre-printed labels to packaging. This label applicator features increased throughput, reliability, and durability for diverse product requirements.

Our PharmaFold solution applies a secondary label that “flags” from the side of a bottle without covering the primary label. This additional label can provide patient information or additional instructions related to the prescription.

Our PharmaWrap labeling automation solution wraps a primary label around the curved surface of the bottle, consistently and accurately every time.

From finer items like welding wire to larger items such as hoses/tubing, a flag labeling system will apply your labels fast, efficiently, and accurately.

apply pre-printed labels directly to products using our Tamp Applicator.

Unlike other systems, we utilize blank label stock, with sequential numbers printed incrementally as you need them. This eliminates the need for purchasing expensive pre-printed labels and guarantees your numbers are not duplicated or out of sequence.

Both our pneumatic and all-electric applicators can be configured in a variety of ways to best serve your unique situation and size requirements, providing consistent and accurate placement of the LPN to your pallets, cartons, or items.

Simplify Cross-dock labeling with our print and apply solutions to increase production and accuracy.

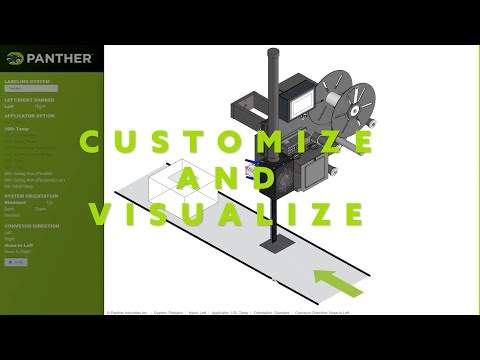

Plan, customize, and visualize your Panther labeling automation system with the Panther Virtual System Builder.