ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn morePhantom Printer Applicator

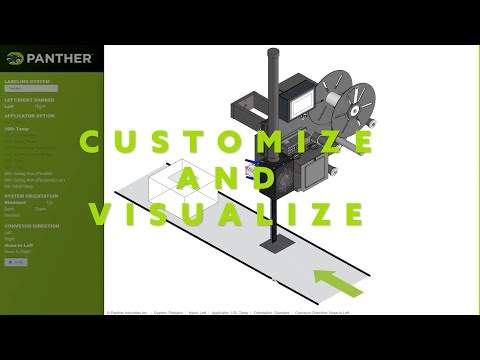

Hi, I'm Brian Baker, Account Manager at Panther Industries. This video highlights our premier pneumatic labeling automation system, the Panther Phantom, which utilizes a blow-on application process.

During application, the tamp head of this system is extended to close proximity with the item to be labeled. Once the item is presented, a blast of compressed air blows the label onto the item so it is affixed for use.

There are multiple benefits of using blow-on label application. First, products don't move when the label is applied, as there is no direct contact with the item. Second, uneven products receive a blow-on label more effectively than a tamp or wipe-applied label. This approach is ideal for produce, where direct contact may damage or otherwise render the food product unusable.

With OEM print engine integration from Zebra, Sato, or Honeywell, the pneumatic labeling solution can be custom configured to align with your specific print engine requirements. Built for speed, accuracy, and reliability, Panther's Phantom blow-on labeling solution will increase your throughput, reduce your expenses, and decrease waste or loss due to outdated processes in your business.