Join us at Pack Expo Chicago and experience best-in-class processing and packaging solutions

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn morePrint & Apply

Samples of Panther printer applicators applying labels to cases and trays.

This feature-rich – and all-electric label automation system is a durable, reliable option for exceptional print and apply performance.

The Panther Phantom is the evolution of label automation uptime. Featuring numerous applicator options, this system can be custom-configured to address your specific requirements to achieve maximum throughput.

A compact, pneumatic printer applicator for on-demand printing solutions that features configurable applicators for your case, flat item, packaging, and product labeling and barcode needs.

An entry-level on-demand labeling solution for greater integration into your growing operation.

A great solution for smaller volume operations that are looking to grow their label automation fulfillment processes.

This innovative solution moves Panther printer applicators on a vertical axis to apply labels to cases and trays, as well as pallets at varying heights.

How can you label a pallet so that your forklift operator spends the maximum amount of time moving pallets and not incurring potential work-related injury by exiting and re-entering the forklift? Simple – by installing a Panther Industries print-and-apply system.

Whether it is a result of non-performing equipment, the need for additional production lines, or addressing manual procedures when preparing your outbound items, your bottom line could benefit from a boost in throughput.

Automate the pack slip and shipping label process with a solution from Panther Industries. Eliminate the labor-intensive process of an operator printing a pack list, folding it, placing it in an envelope, and then manually applying it to a package.

By utilizing tandem Predator printer applicators, remove the labor-intensive process of an employee printing, folding, and applying a pack slip and shipping label to your case or carton with our shipping and pack slip automation process.

With our NEXTStep label applicator, a shipping label and pack slip are printed simultaneously, folded, then applied to the item.

Ideal for carton and pallet labeling applications that features a durable carbon fiber swing arm that allows for various label sizes to be applied fast, and accurately.

Apply corner wrap labels to your cases and trays using the merge applicator with a brush-on option.

Utilize tandem printer applicators to increase throughput and efficiency when variable height labeling is a must.

The NEXTStep eliminates the need to manually print, fold, and apply a separate pack slip to your outbound package.

For increased throughput and efficiency, utilize tandem Predator Printer Applicators for all your cases and tray labeling needs.

Tandem Predator Printer Applicators applying secondary barcode labels to the side of cases.

Our fastest, most adaptive label application system ever. The Predator is built for speed – and accuracy – to boost your throughput and elevate your business.

Utilize Panther print-and-apply labeling systems in cross-dock and outbound shipping operations, warehouse, distribution, and fulfillment centers are able to improve their overall efficiency and throughput.

A linear applicator for top and side label applications – primarily on packages, products, or pallets that are stationary or in motion.

Featuring numerous applicator options, this system can be custom-configured to address your company’s requirements to achieve maximum throughput.

By utilizing tandem Phantom Printer Applicators, eliminate downtime and increase productivity.

Label two sides of cases, trays, or bins utilizing tandem Phantom Printer Applicators with our Wipe Applicator.

Our Shadow Printer Applicator with optional mounting stand allows for small production line labeling automation.

Our swing arm applicator configuration allows you to apply labels to the front, side, front + side, and corner wrap cases and trays as well as pallets.

With a swing arm application, labels can be applied to the front, side, both front and side, or around the corner of an item.

From cases and trays to pallets and bins, utilize our swing arm applicator for front and side labeling automation.

Utilizing our Swing Arm Applicator, you can apply longer labels with limited height availability to cases and trays.

Using tandem Printer Applicators, label various size cases and trays with ease.

Apply larger labels utilizing our customer Swing Arm Corner Wrap Applicator to label cases and trays.

The swing blow applicator features a swing arm that presents the label prior to application on the front, side, or top of an item. The label is then blown onto the surface with minimal contact from the applicator surface.

The tandem swing blow applicators apply labels to assorted cases and feature a swing arm that presents the label prior to application on the front, side, or top of an item. The label is then blown onto the surface with minimal contact from the applicator surface.

Unlike other systems, we utilize blank label stock, with sequential numbers printed incrementally as you need them. This eliminates the need for purchasing expensive pre-printed labels and guarantees your numbers are not duplicated or out of sequence.

Both our pneumatic and all-electric applicators can be configured in a variety of ways to best serve your unique situation and size requirements, providing consistent and accurate placement of the LPN to your pallets, cartons, or items.

Simplify Cross-dock labeling with our print and apply solutions to increase production and accuracy.

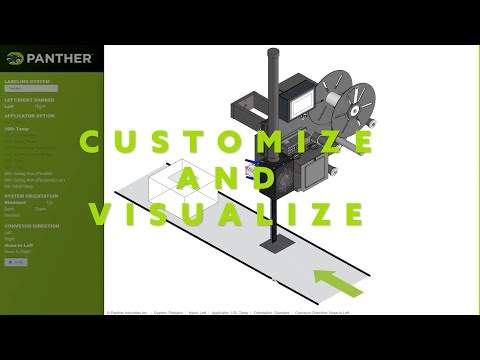

Plan, customize, and visualize your Panther labeling automation system with the Panther Virtual System Builder.